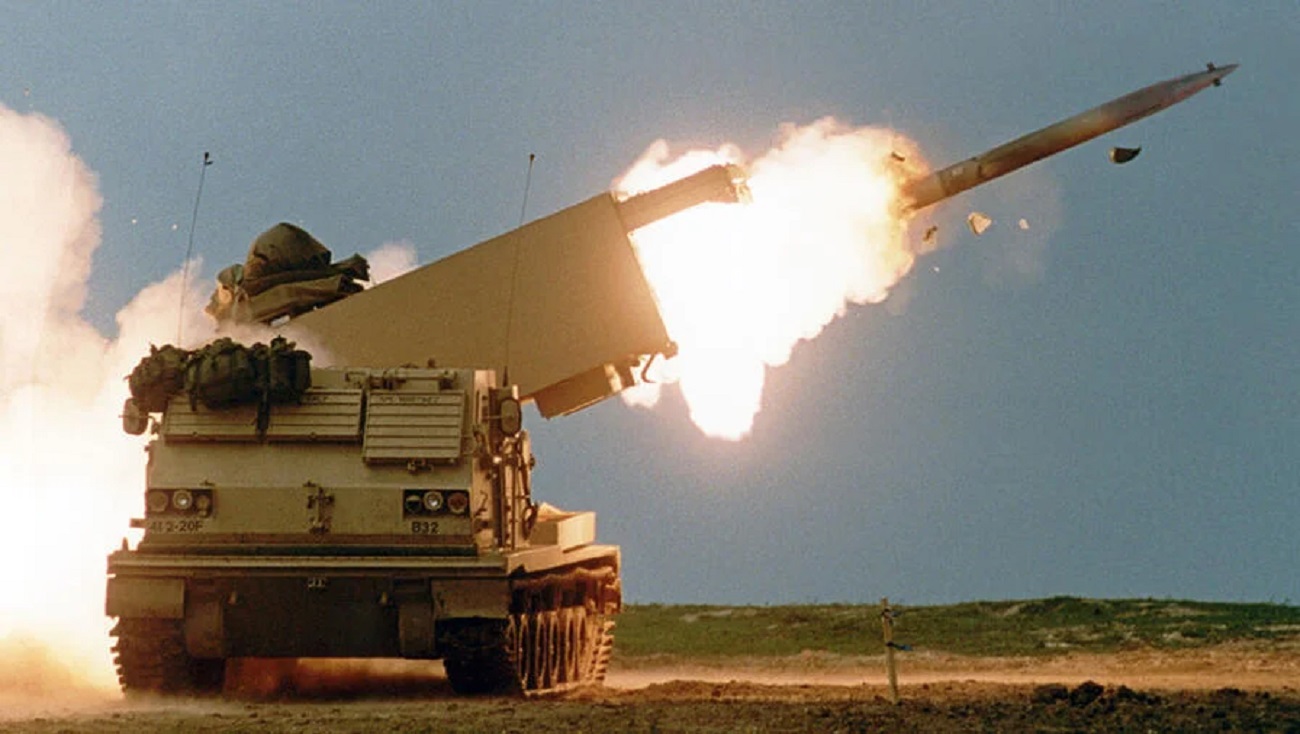

Aerojet Rocketdyne, a subsidiary of L3Harris Technologies, is embarking on a transformative journey with substantial upgrades to its solid rocket motor manufacturing facilities. This strategic initiative is driven by a recent contract secured from Lockheed Martin, marking a pivotal milestone in the continuous provision of propulsion systems for the U.S. Army’s Guided Multiple Launch Rocket System (GMLRS) program.

“Aerojet Rocketdyne’s proven propulsion has been the driving force behind the GMLRS for decades. Our commitment is unwavering, with a strategic vision to further automate processes and modernize facilities throughout 2024. These initiatives are poised to elevate efficiency, ensuring the seamless delivery of this crucial component integral to the GMLRS program,” affirmed Tyler Evans, President of Aerojet Rocketdyne’s Missile Solutions sector. In articulating this dedication, Aerojet Rocketdyne not only solidifies its legacy as a propulsion leader but also paves the way for continued excellence in GMLRS advancement.”

.

Aerojet Rocketdyne’s proven propulsion has been the driving force behind the GMLRS for decades. Our commitment is unwavering, with a strategic vision to further automate processes and modernize facilities throughout 2024. These initiatives are poised to elevate efficiency, ensuring the seamless delivery of this crucial component integral to the GMLRS program,” affirmed Tyler Evans, President of Aerojet Rocketdyne’s Missile Solutions sector. In articulating this dedication, Aerojet Rocketdyne not only solidifies its legacy as a propulsion leader but also paves the way for continued excellence in GMLRS advancement

Aerojet Rocketdyne stands as the sole company capable of producing both steel- and composite-cased motors for GMLRS. This distinction is crucial as GMLRS boasts a formidable range exceeding 70 kilometers. This collaboration not only fortifies Aerojet Rocketdyne’s position as an industry leader but also underscores its unique capability to contribute to the diverse needs of modern missile technology.